01 Product Description

SF-PVROOF03 BIPV Waterproof Shed (Steel) redefines durability and adaptability in building-integrated photovoltaics, combining robust steel construction with advanced solar energy generation. Designed as a high-strength, eco-friendly alternative to traditional skylights, this system delivers reliable performance in waterproofing, wind resistance, snow loading, and natural light transmission—all while generating clean electricity.

Customization lies at the core of the SF-PVROOF03. With in-house steel processing capabilities, Solar First delivers structures tailored to specific site conditions, ensuring optimal fit and performance. The use of hot-dip galvanized high-strength carbon steel enhances corrosion resistance, stability, and service life, supporting snow loads up to 35 cm and wind speeds of 42 m/s in accordance with EN13830.

A key innovation is the adjustable light transmittance of PV modules, ranging from 10% to 80%, making the system suitable for spaces with varying daylight requirements. Ideal for installation on houses, villas, rooftops, or as a standalone waterproof structure, the SF-PVROOF03 mergs engineering excellence with functional elegance.

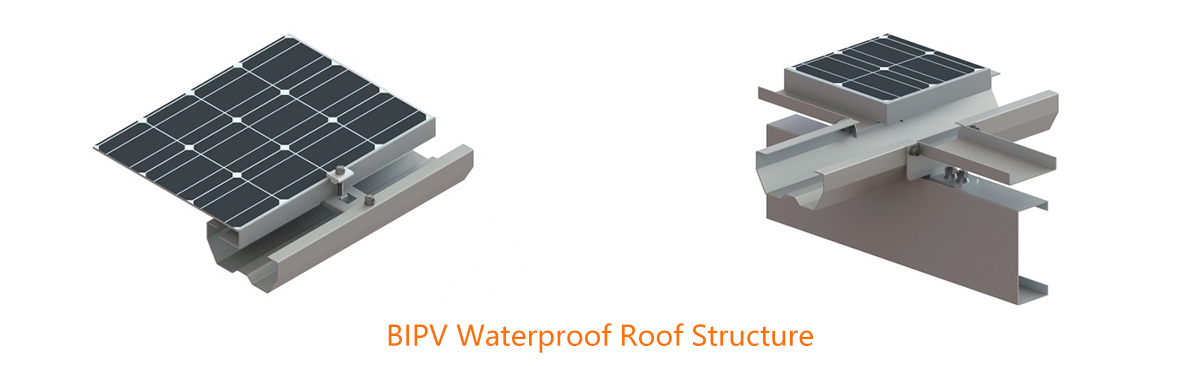

02 Accessory schematic diagram

03 Core Engineering Parameters

| Key indicators | Parameter details |

| Installation | BIPV Roof |

| Wind Load | up to 60m/s |

| Tilt Angle | ≥3° |

| Snow Load | 1.4kn/m² |

| Standards | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50017-2017 |

| Material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304, Hot Dip Galvanized Steel |

| Warranty | 10 Years Warranty |

04 Industry Application Scenarios

✔ Waterproof canopy for villa terrace

✔ Factory roof extension shed

✔ Independent courtyard photovoltaic shed

05 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

06 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

07 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

08 Project Case

leave a message

Scan to wechat :