01 Product Description

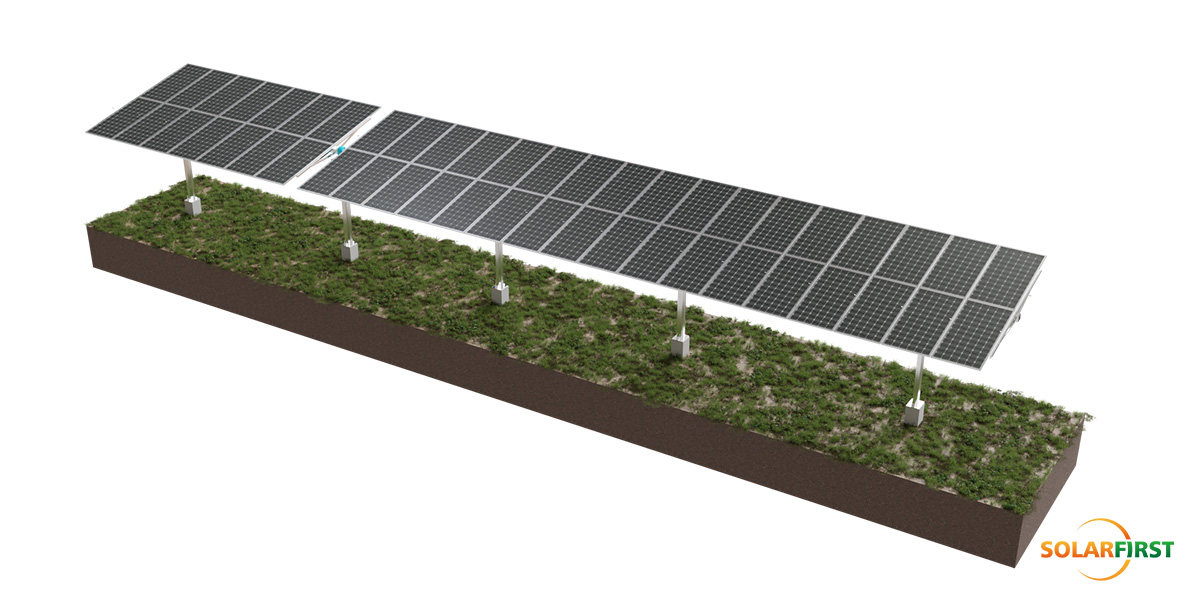

This horizontal single axis tracker is engineered to significantly enhance energy output by continuously aligning solar panels with the sun throughout the day. Designed for utility-scale and large commercial solar projects, the system combines high adaptability, structural stability, and intelligent control to maximize power generation across diverse terrains and weather conditions.

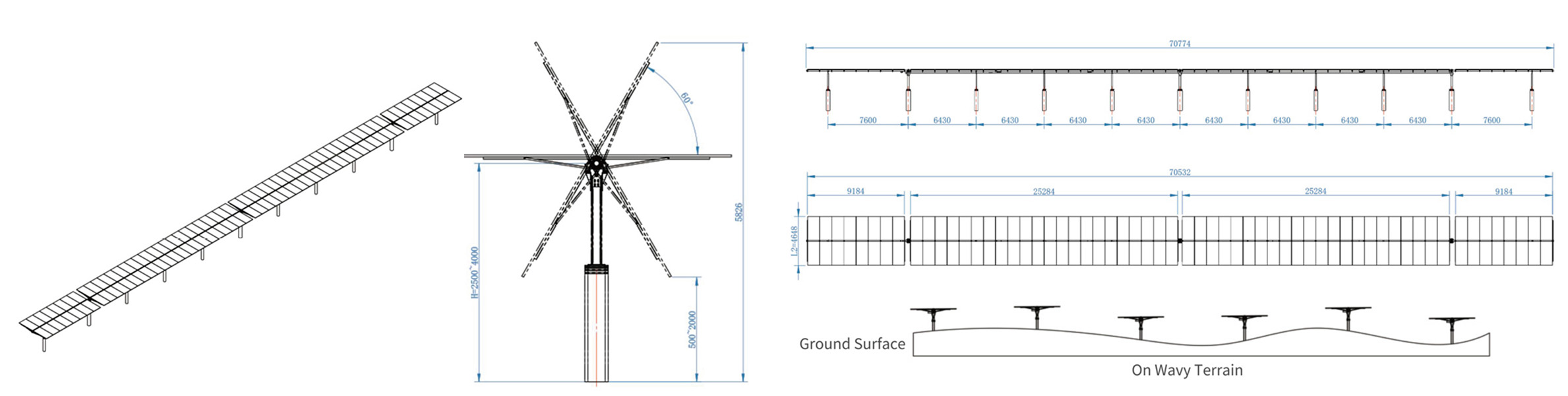

Featuring a gradient adaptability of up to 15% in North-South direction, the tracker performs reliably on uneven terrain. Its multi-point drive system substantially improves wind torsion resistance and raises critical wind speed tolerance, supporting stable operation in winds up to 45 m/s. Compatible with both 182mm and 210mm cell solar modules, each tracker can accommodate up to 120 modules and is configurable for 1000V or 1500V system voltage.

The smart tracking system adjusts the tilt angle (up to ±45°) in real time using terrain and weather data, while an independent monitoring system ensures operational reliability and quick fault detection. Built with hot-dip galvanized and Zn-Al-Mg coated steel (≥65μm coating thickness), the tracker offers long-term corrosion resistance and is available with PHC, cast-in-place, or steel pile foundations.

Whether deployed in solar power plants or large commercial installations, this system provides an optimal balance of performance, durability, and ease of maintenance.

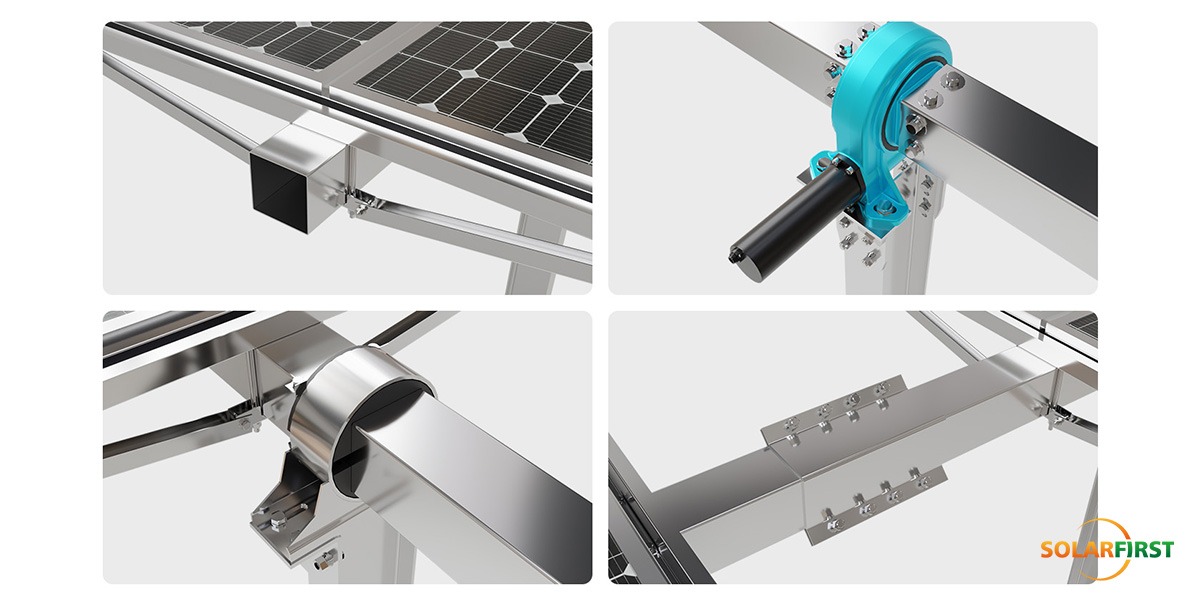

02 Accessory schematic diagram

03 Product Components

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Tracking Technology | Horizontal Single Axis Tracker |

| System Voltage | 1000V/1500V |

| Tracking Range | ±45° |

| Working Wind Speed | 18 m/s (Customizable) |

| Max. Wind Speed | 45 m/s ASCE 7-10 (Customizable) |

| Modules per Tracker | ≤120 Modules (Customizable) |

| Principal Materials | Hot-Dip Galvanized Q235B/Q355B, Zn-AI-Mg Coated Steel |

| Mean Coating Thickness | ≥65μm |

| Drive System | Slewing Drive / Linear Actuator |

| Foundation type | PHC / Cast-in-Place Pile / Steel Pile |

05 Industry Application Scenarios

✔ Deserts and marginal lands: Applicable systems: Single-axis and dual-axis tracking systems

✔ Slopes and undulating terrain: Applicable systems: Inclined single-axis/adaptive dual-axis systems

✔ Rooftop photovoltaic and community power supply: Applicable systems: Light-duty flat single-axle/small-sized dual-axle systems

06 Professional technical services

▶ Solution design and structural analysis:

Provide customized solution drawing, load calculation reports (including wind load/snow load/seismic force analysis) or assembly drawing.

▶ On-site survey:

Engineers conduct on-site investigations ground conditions with local soil investigation professionals.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site installation guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :