This versatile L-foot mounting system accommodates corrugated, trapezoidal, and asbestos roofing sheets, with multiple fastener options for fast and secure installation. Fully compliant with international wind and snow load standards, it ensures reliability across diverse climates.

Color :

Natural silver/ black(Colored according to customer requirements)Material :

Anodized Aluminum 6005 T5, Stainless Steel 304Certification :

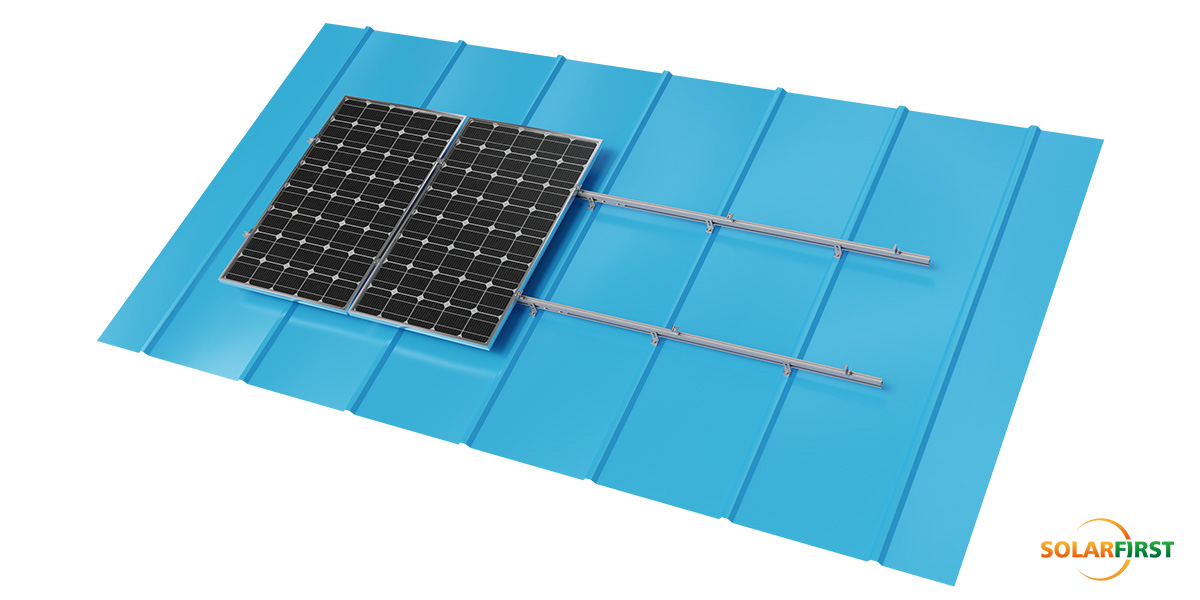

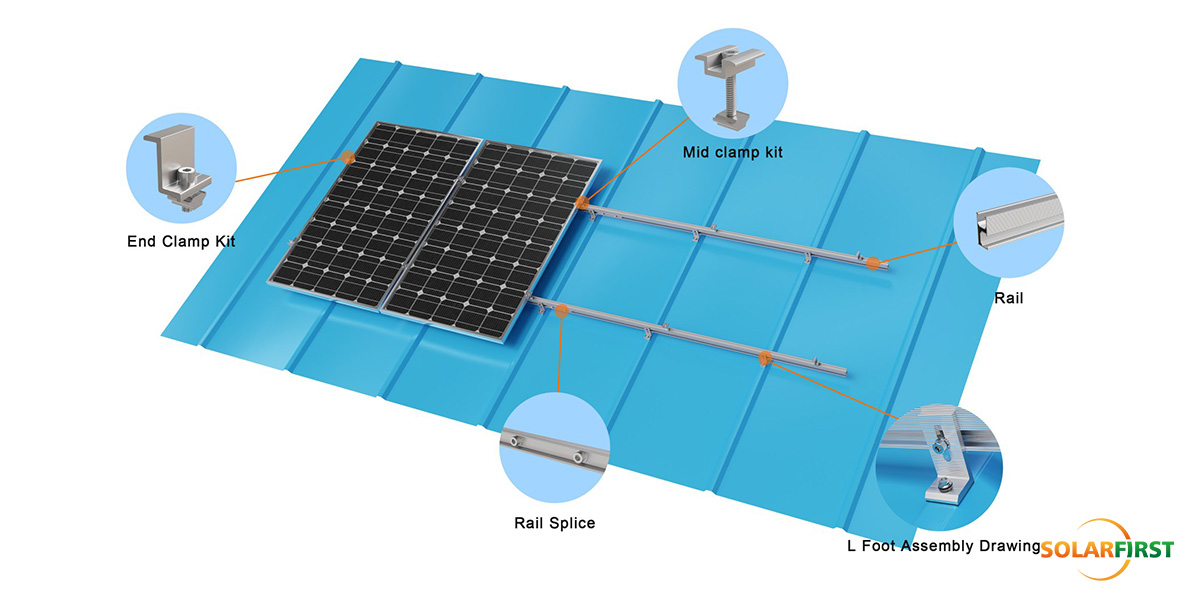

ISO,SGS,CEEngineered for trapezoidal metal roofing, this solar mounting system delivers a secure and efficient racking solution. Its low-profile, aluminum alloy construction ensures rapid installation while significantly reducing structural load.

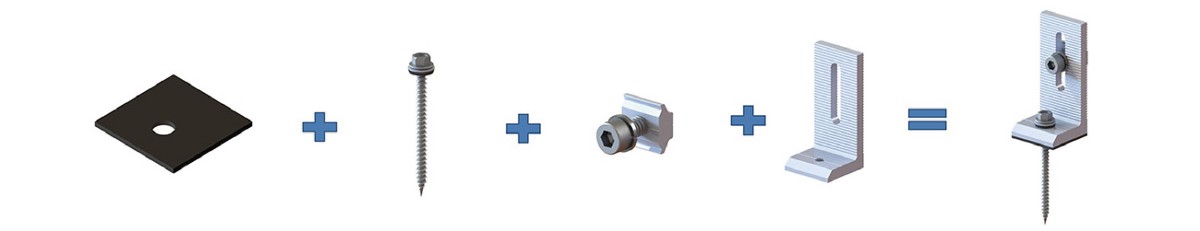

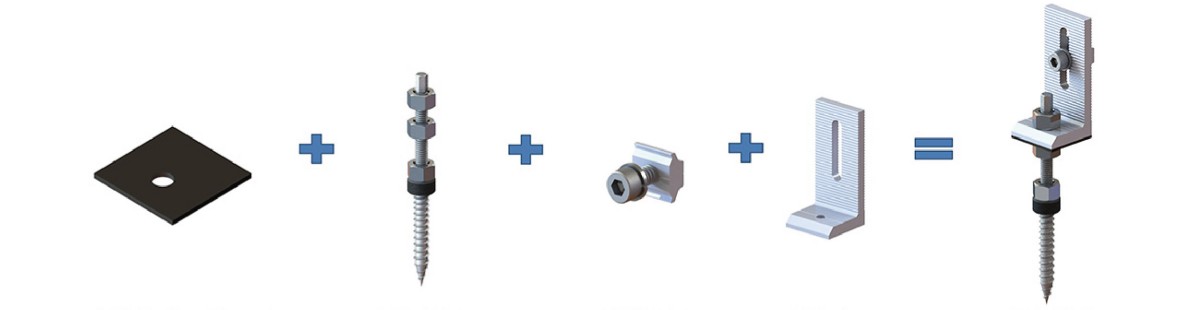

The universal L-foot bracket is compatible with a wide range of trapezoidal profiles and can be seamlessly integrated with hanger bolts to achieve the desired module elevation.

The L foot can also be used with other types of roof clamps, such as Klip Lok roof clamps, to elevate the solar panels.

| Key indicators | Parameter details |

| Applicable roof | Trapezoid Type metal tile roof |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | Parallel to the roof |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50429-2007 |

| Warranty | 10 Years Warranty |

05 Applicable scenarios

✔ Manufacturing factory: Roof of automotive/electronic factory buildings

✔ Cold chain logistics center: Large warehouse roof

✔ Agricultural greenhouse upgrade: Light steel frame greenhouse

06 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 FAQ

Q: What types of roofs are compatible with the L-foot support system?

A: The L-foot solar mounting system is primarily designed for use on corrugated or trapezoidal profiled metal (color steel) roofs.

Q: How is the L-foot bracket system installed?

A: The system features a professional design where the support base is securely attached to the roof sheets using double-tooth screws or similar fasteners. Installation follows standard roofing system practices: clamps are fixed on both sides of the trapezoidal sheeting, or bolts are drilled into the trapezoidal cross-section. Rubber sealing pads are used throughout to maintain waterproof integrity.

Q: How does the L-foot system ensure waterproofing?

A: Watertight protection is achieved through the use of rubber sealing pads, especially in applications where bolts are drilled into the trapezoidal cross-section of the metal sheets.

Q: Are custom L-foot mounting solutions available?

A: Yes, Solar First provides customized photovoltaic mounting solutions tailored to specific project requirements.

09 Project Case

leave a message

Scan to wechat :