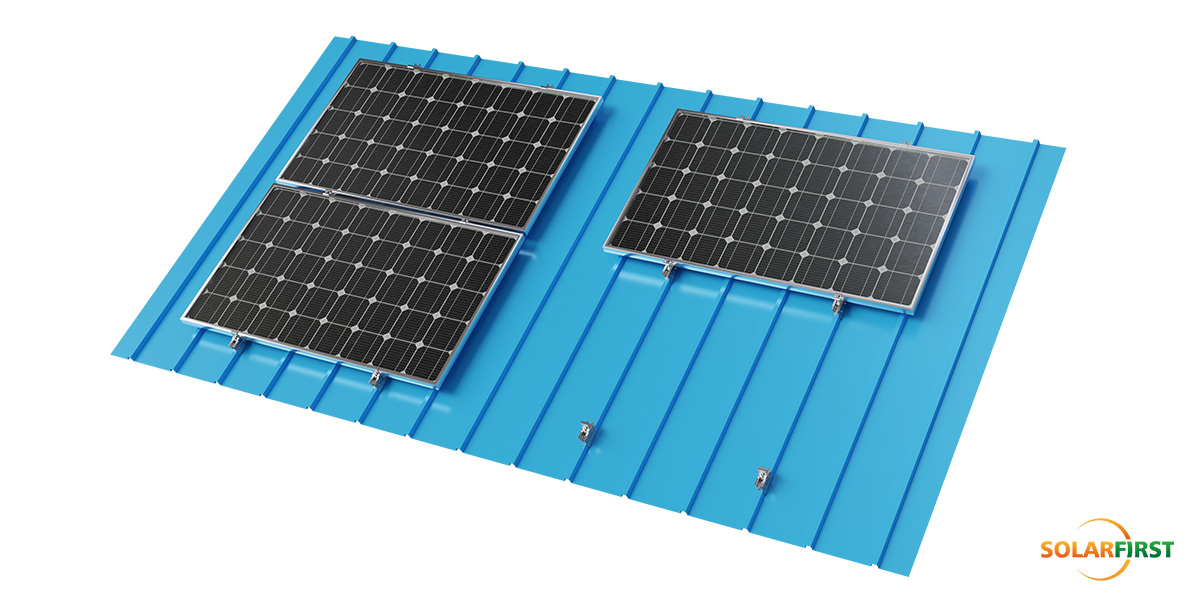

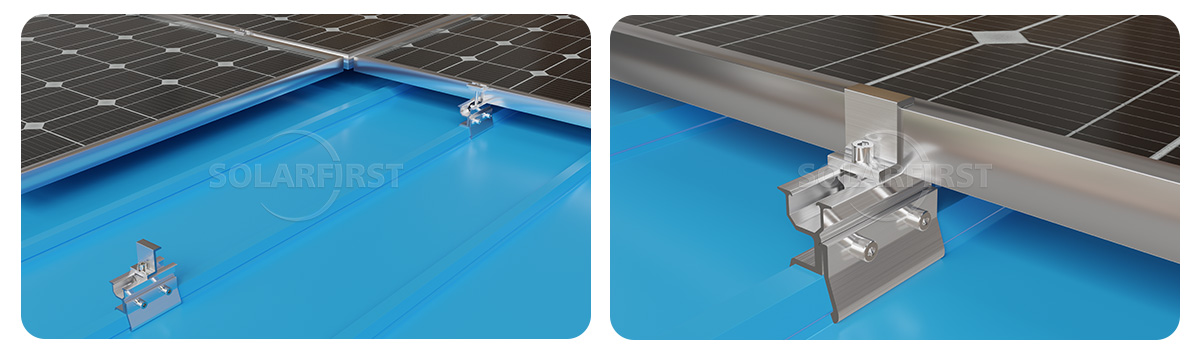

This system is specifically designed for trapezoidal metal roofs, enabling quick and safe installation through pre-assembled modular kits, and serves as a reliable support platform for various framed and frameless solar modules.

Color :

Natural silver/ black(Colored according to customer requirements)Material :

Anodized Aluminum 6005 T5, Stainless Steel 304Certification :

ISO,SGS,CE01 Product Description

Achieve maximum savings on trapezoidal metal roofs with our all-in-one non-penetrating system.

The unique integrated rail design allows for direct panel attachment, cutting out the cost and complexity of conventional racking. This slashes installation time and dramatically reduces overall project expenses.

Designed to be lightweight and low-profile, it places minimal stress on your roof structure. Furthermore, it offers remarkable adaptability with custom minirail clamps available for a wide range of profiles, such as Klip Lok and Seam Lok.

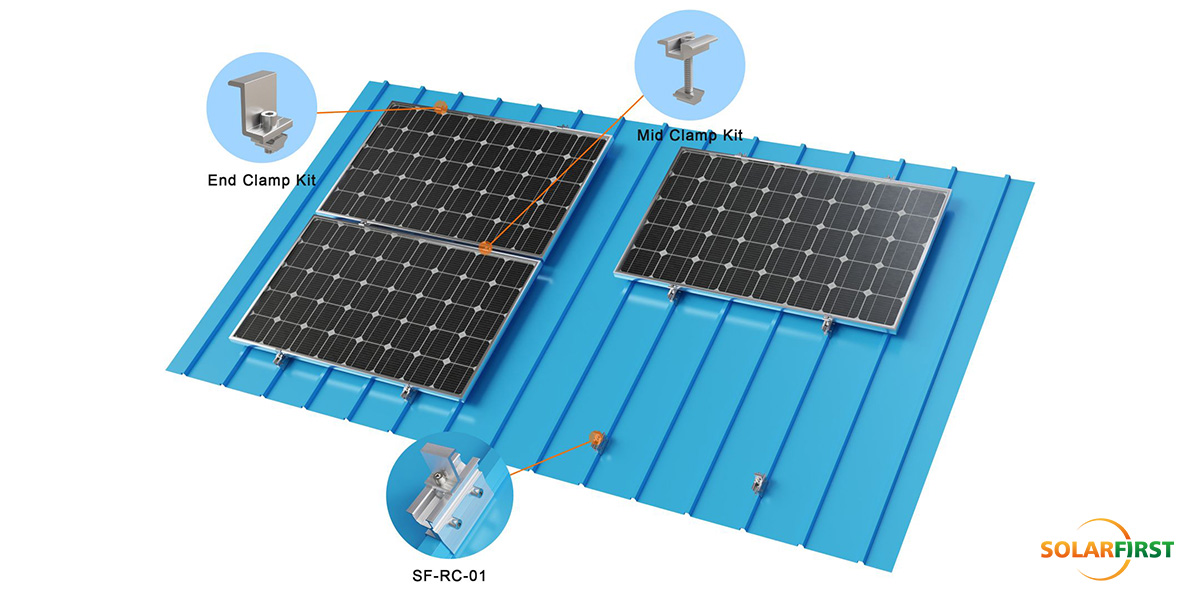

02 Accessory schematic diagram

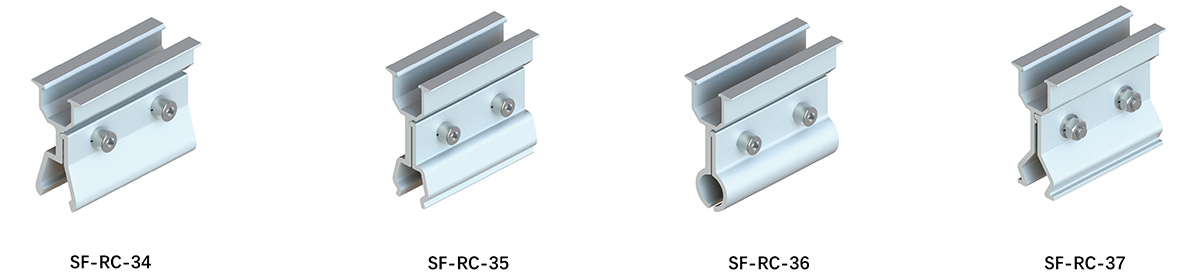

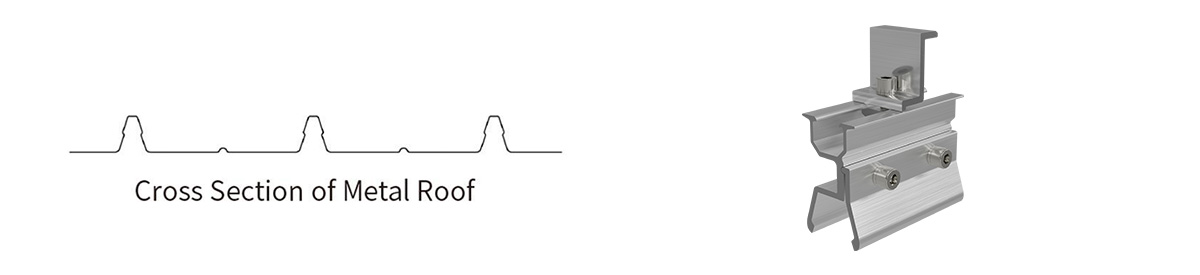

03 Product Components

| Dimensions (mm) | A | B | C | D |

| SF-RC-34 | 12.7 | 19.1 | 24.5 | 20.2 |

| SF-RC-35 | 17.9 | 13.8 | 25 | 16.2 |

| SF-RC-36 | 0 | 10.1 | 20.2 | 7.1 |

| SF-RC-37 | 0 | 12.3 | 24.6 | 14.7 |

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Metal Roof |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | Parallel to the roof |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50429-2007 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Manufacturing factory: Roof of automotive/electronic factory buildings

✔ Cold chain logistics center: Large warehouse roof

✔ Agricultural greenhouse upgrade: Light steel frame greenhouse

06 Product Features

▶ Economical and efficient, with rapid deployment:

The system is delivered in a pre-assembled modular kit format. All components are integrated and packaged, eliminating the need for complex processing on-site. This significantly reduces installation time and labor costs, accelerating the project's return on investment cycle.

▶ Sturdy and reliable, safe and durable:

From material selection to structural design, all aim at long-term outdoor service. The combination of high-strength aluminum alloy tracks and corrosion-resistant fasteners ensures that the system remains stable even in environments such as rain, salt spray, and ultraviolet rays.

▶ Flexible adaptation, multi-functional:

Offers "project-based design" flexibility, capable of flexibly configuring the support components according to different metal roof models and component specifications, achieving "one system, multiple scenarios" coverage.

▶ Easy maintenance, almost maintenance-free:

Once installed, the system requires almost no additional maintenance throughout its entire lifecycle, providing users with a worry-free and reliable usage experience.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :