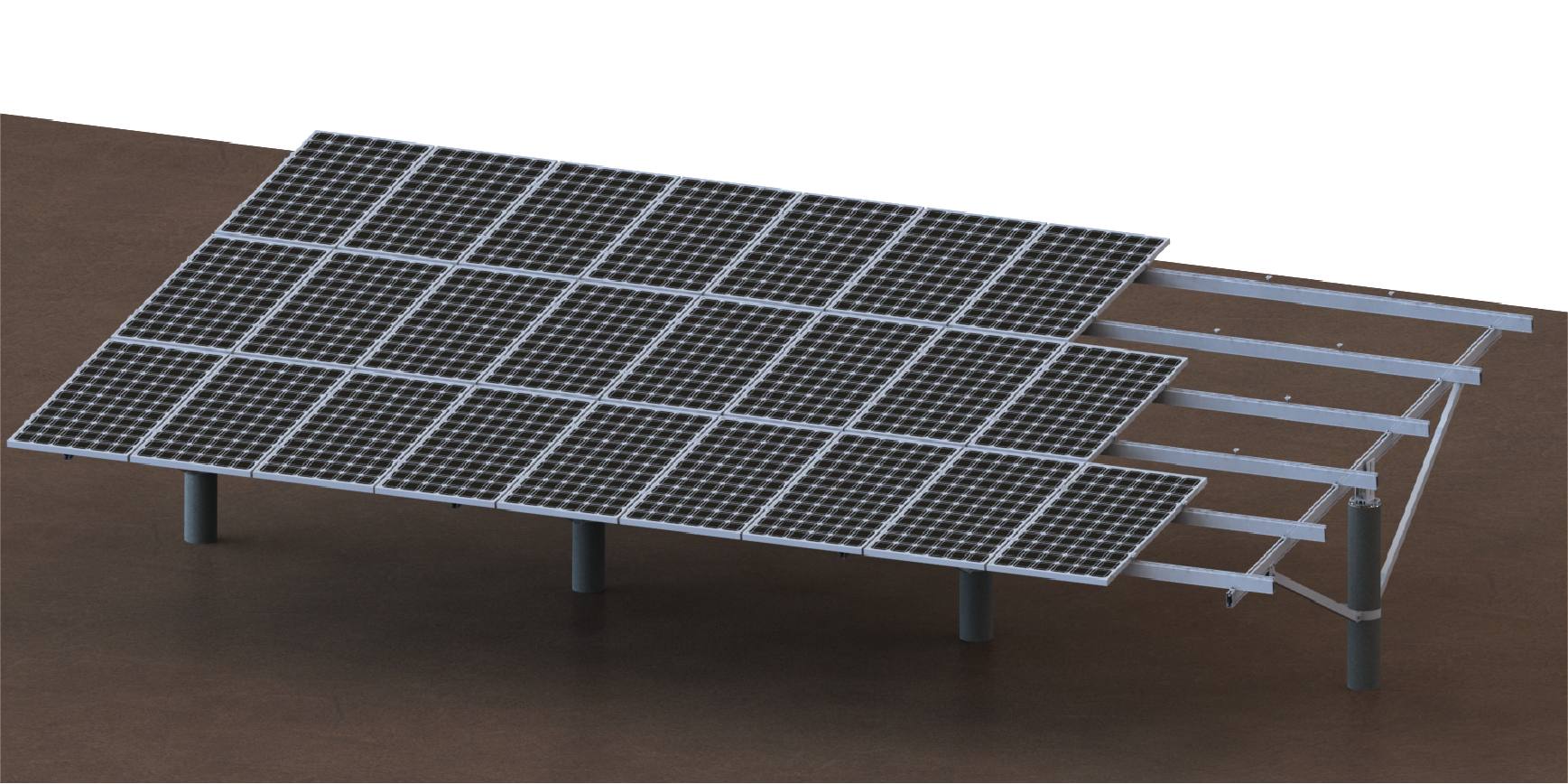

01 Product Description

The PHC aluminum ground mounting system is an innovative solar racking ground mount solution designed for commercial and utility-scale solar parks, including fishery PV projects. Utilizing pre-stressed high-strength concrete (PHC) spun piles as foundations, this system requires no earth excavation, significantly reducing environmental impact and simplifying installation across diverse terrains such as fish ponds, mud flats, slopes, and inter-tidal zones.

Engineered with high-strength anodized aluminum AL6005-T5 and corrosion-resistant materials, the structure delivers exceptional durability and reliability under challenging conditions, supporting wind loads up to 60m/s and snow loads of 1.4 kN/m². The pre-fabricated PHC piles allow fast installation, minimize maintenance, and provide adaptability for high-clearance or flood-prone areas.

This solar ground mount kit combines efficient design, environmental compatibility, and cost-effectiveness, making it an ideal choice for large-scale projects where traditional foundations are not feasible.

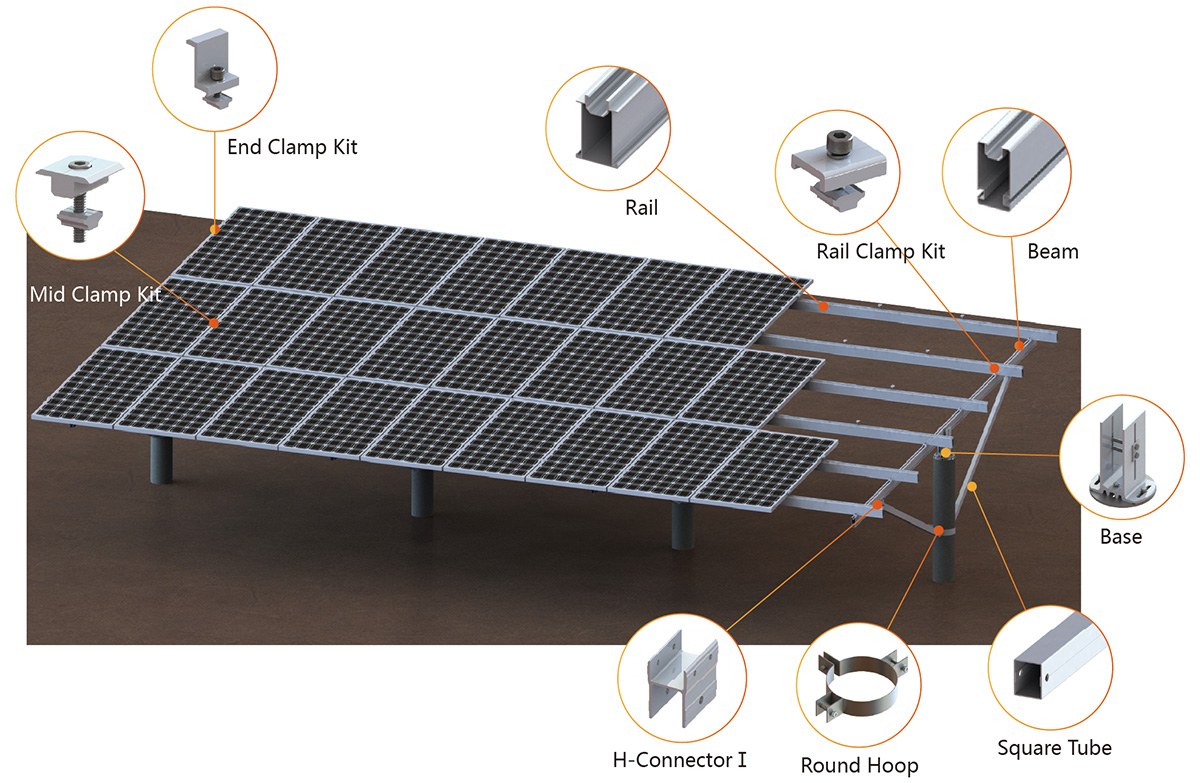

02 Accessory schematic diagram

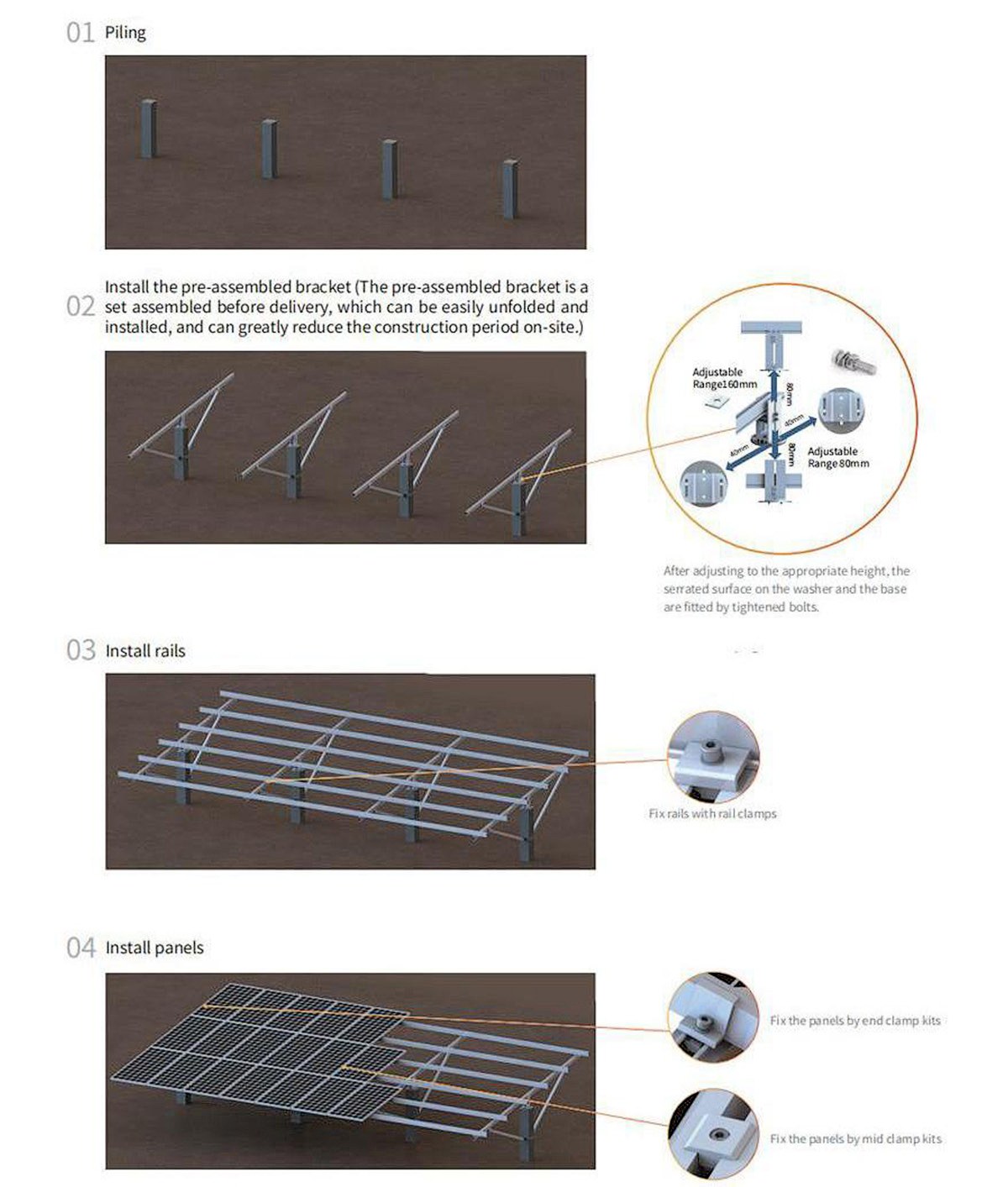

03 Installation Steps

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Ground |

| Foundation | Concrete Spun Pile / High Concrete Pile (H≥600mm) |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Main material | AS/NZS1170, JIS C8955:2017, GB50009-2012, DIN 1055, IBC 2006 |

| standard | Anodized AL6005-T5, Hot Dip Gavanized Steel, Stainless Steel SUS304 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Fishery pond surface Photovoltaic power Station (Fishery and Photovoltaic Complementary)

✔ Tidal flat/intertidal zone photovoltaic projects

✔ Mountain power Station

✔ Soft geological areas such as mudflats

06 Professional technical services

▶ Solution design and structural analysis:

Provide customized solution drawing, load calculation reports (including wind load/snow load/seismic force analysis) or assembly drawing.

▶ On-site survey:

Engineers conduct on-site investigations ground conditions with local soil investigation professionals.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site installation guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :