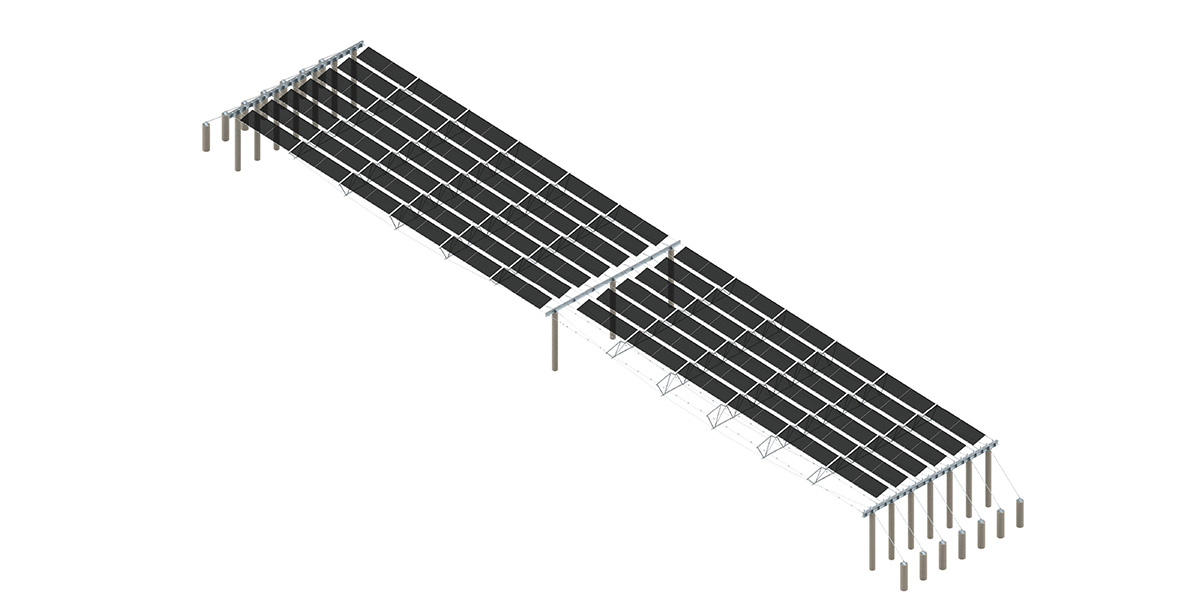

01 Product Description

The double-layer cable flexible support system achieves a revolutionary span of ≤50 meters through a spatial cable net structure, creating an operation clearance of ≤6 meters. Compared with fixed supports, it reduces the amount of pile foundation usage by 55%, and is perfectly suitable for scenarios such as sewage treatment plants, agricultural photovoltaic complementarity, and fishery photovoltaic complementarity, and complies with the GB50017-2017 Steel Structure Design Code.

✅ Super-large span technology

• 50-meter unsupported crossing (conventional scheme requires 8-10 piles)

• Pile foundation quantity ↓55% (Empirical data)

✅ High-stiffness pseudo-wind resistance

• The double-layer cable net structure suppresses wind-induced vibration

• Passed the 0.45KN/m² dynamic wind vibration test (JGJT 497-2023)

✅ Harsh terrain adaptation

• Lay directly on a slope of ≤10° (no site leveling required)

✔ Sewage treatment plant ✔ Sloping land ✔ Aquaculture ponds

✅ Composite space utilization

• Vertical space support ≤6 meters

✔ Passage of large agricultural machinery ✔ Aquaculture ✔ vegetation growth

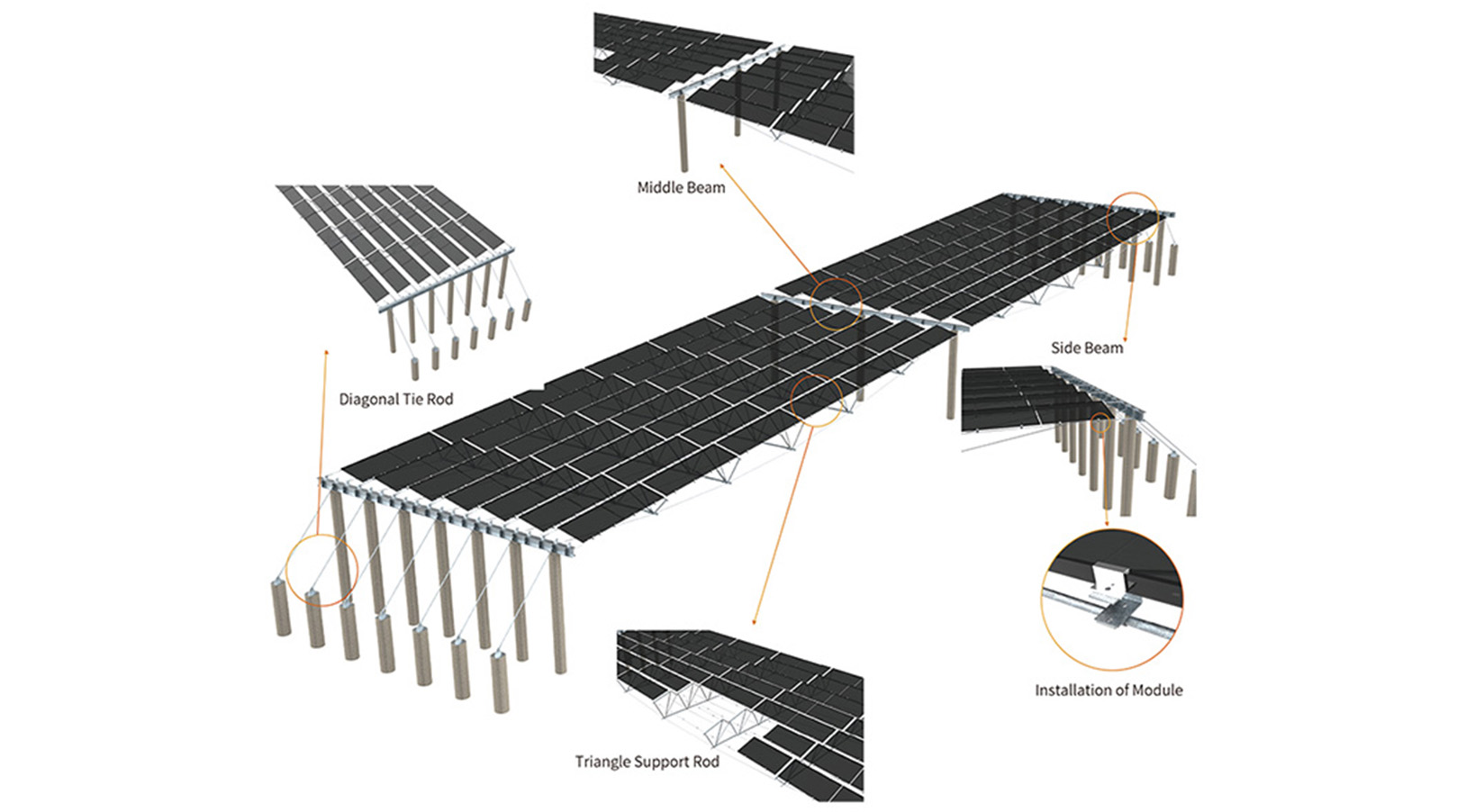

02 Accessory schematic diagram

03 Core Engineering Parameters

| Key indicators | Parameter details |

| Installation | Ground |

| Foundation | PHC/Cast-in-place Pile |

| Modules Layout | Single Row in Portrait |

| Single span | ≤50 m |

| Wind Load | 0.45KN/m² (Adjustable according to the project) |

| Snow Load | 0.15KN/m² (Adjustable according to the project) |

| Tilt Angle | ≤15° |

| Standards | ≥65μm |

| Drive System | GB 50009-2012, GB50017-2017, NB/T 10115-2018, JGJ257-2012, JGJT 497-2023 |

| Material | Anodized Aluminum AL6005-T5, Hot Dip Galvanized Steel, Zn-AlMg pre-coated steel,Stainless SteelSUS304 |

| Warranty | 10 Years Warranty |

04 Industry Application Scenarios

✔ Sewage treatment plant

✔ Agrivoltaic complementarity

✔ Fishery-photovoltaic complementarity

05 Professional technical services

▶ Solution design and structural analysis:

Provide customized solution drawing, load calculation reports (including wind load/snow load/seismic force analysis) or assembly drawing.

▶ On-site survey:

Engineers conduct on-site investigations ground conditions with local soil investigation professionals.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site installation guidance to ensure safe and complete installation.

06 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

07 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

08 Project Case

leave a message

Scan to wechat :