01 Product Description

SF Fence is specially designed for on-site protection of projects, ensuring personnel safety and asset theft prevention through a high-strength structure. The slope adaptability meets the requirements of complex terrain, and the simple installation process significantly reduces construction costs. While maintaining high-quality durability, it provides physical protection solutions that are both economical and reliable for power stations and engineering sites.

Core Value

• Double security guarantee

✓ Effectively protect the safety of personnel both inside and outside the project site

✓ Prevent the risk of equipment theft

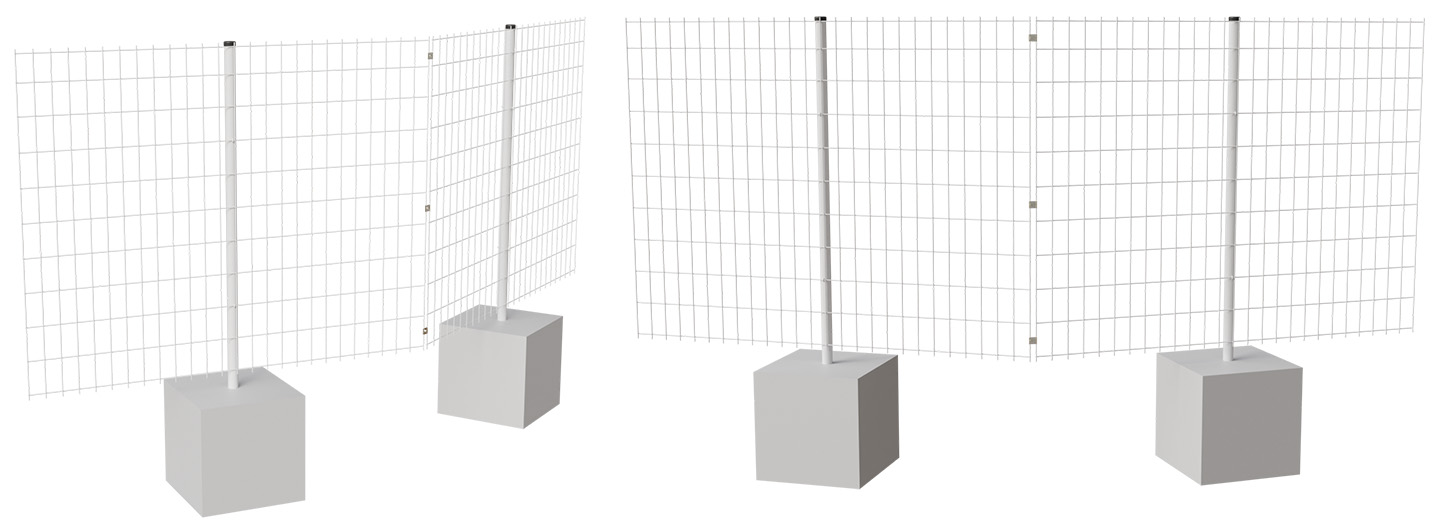

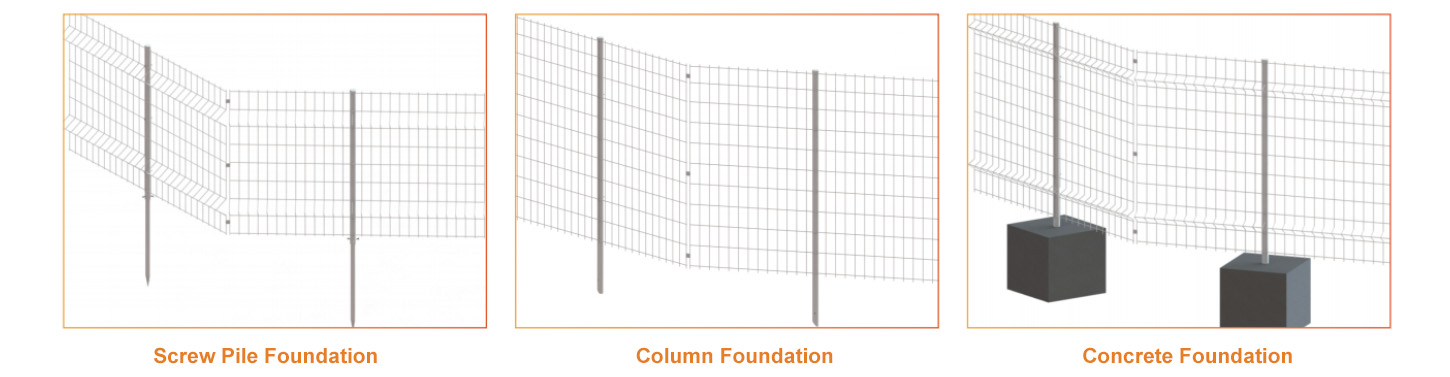

• Strong terrain adaptability: Compatible with deployment on flat land and slopes of a certain gradient

Product advantages

• Efficient installation: The modular structure saves labor costs

• Outstanding performance: High-strength materials ensure high durability

• Economical and practical: A balance between high-quality protection and low-cost investment

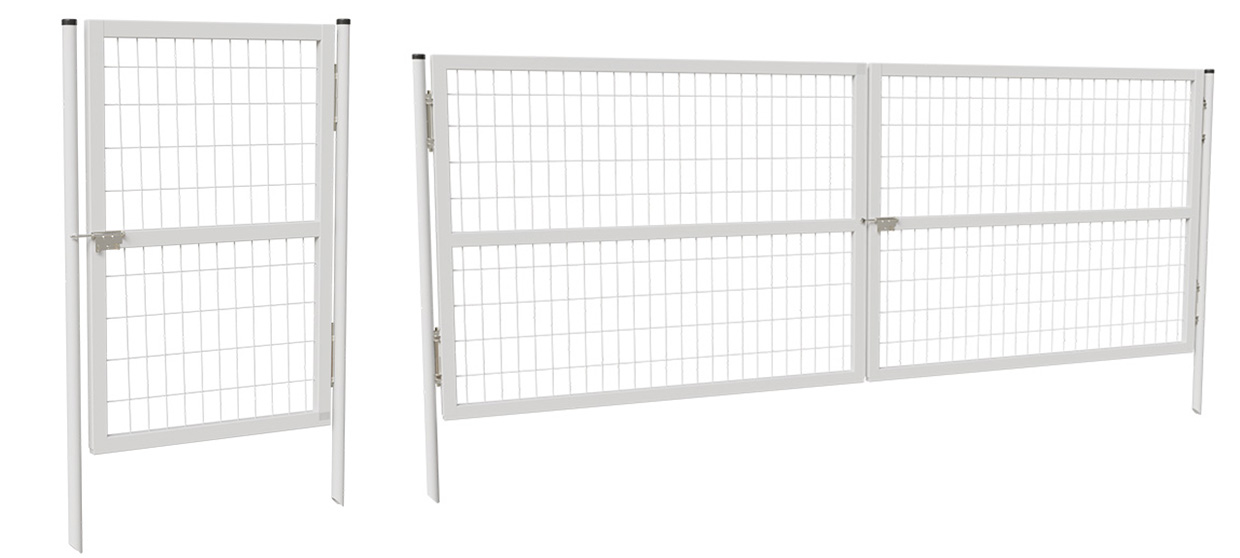

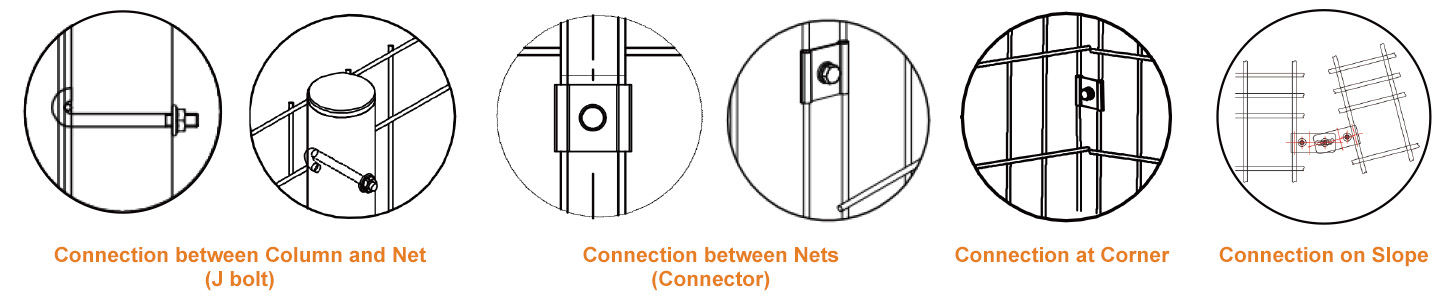

02 Accessory schematic diagram

03 Product Components

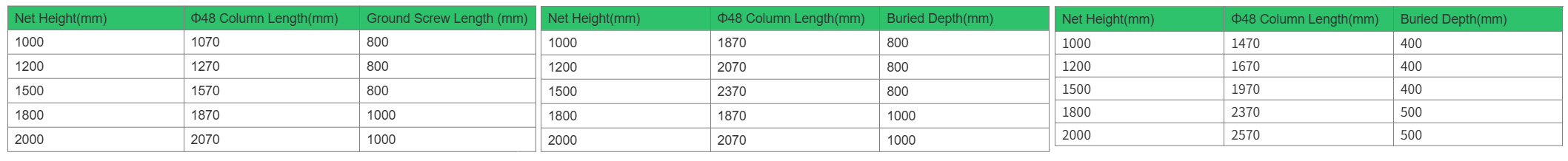

04 Core Engineering Parameters

05 Component List

| No. | Description | Dimension (mm) | Material | Surface Treatment | Unit |

| 1 | Mesh | φ3.5*L2000 | steel | plastic dipping or galvanization | piece |

| 2 | Column | φ48*T2 | steel | plastic dipping or galvanization | piece |

| 3 | Ground Screw | φ38 | steel | hot dip galvanization | piece |

| 4 | Connector | / | aluminum/stainless steel | anodization | set |

06 Industry Application Scenarios

✔ Residential and private domains

✔ Agriculture and Animal Husbandry

✔ Industrial and commercial facilities

✔ Public facilities and places

07 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

08 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

09 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

10 Project Case

leave a message

Scan to wechat :