01 Product Description

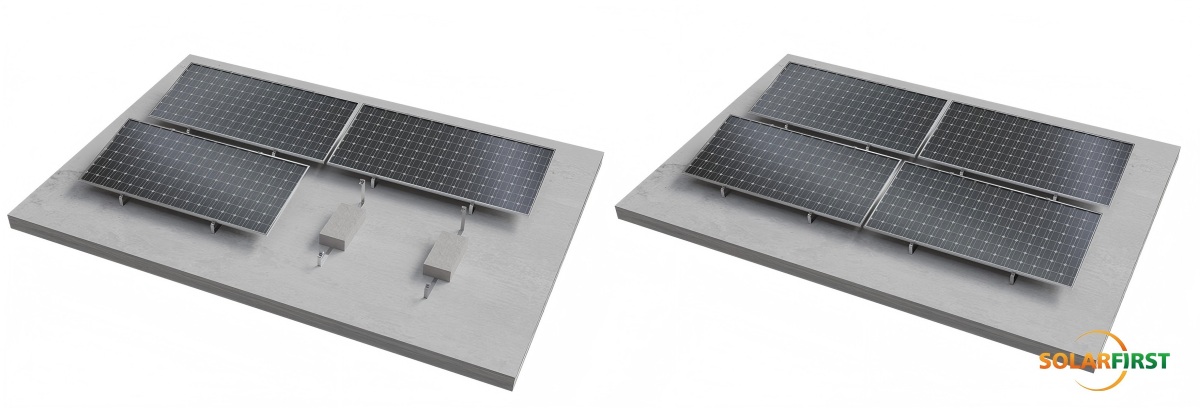

A quick-deployment, non-penetrating system for concrete flat roofs, designed to secure your investment against high wind loads. The innovative, modular ballast plates offer unmatched flexibility, allowing you to fully utilize the available roof space for maximum capacity with your choice of unidirectional or symmetrical layouts.

Built with stainless steel for superior corrosion resistance, the system features easily customizable tilt angles and a straightforward design that significantly reduces installation time. This solution combines durability, efficiency, and smart design for a superior flat roof mounting experience.

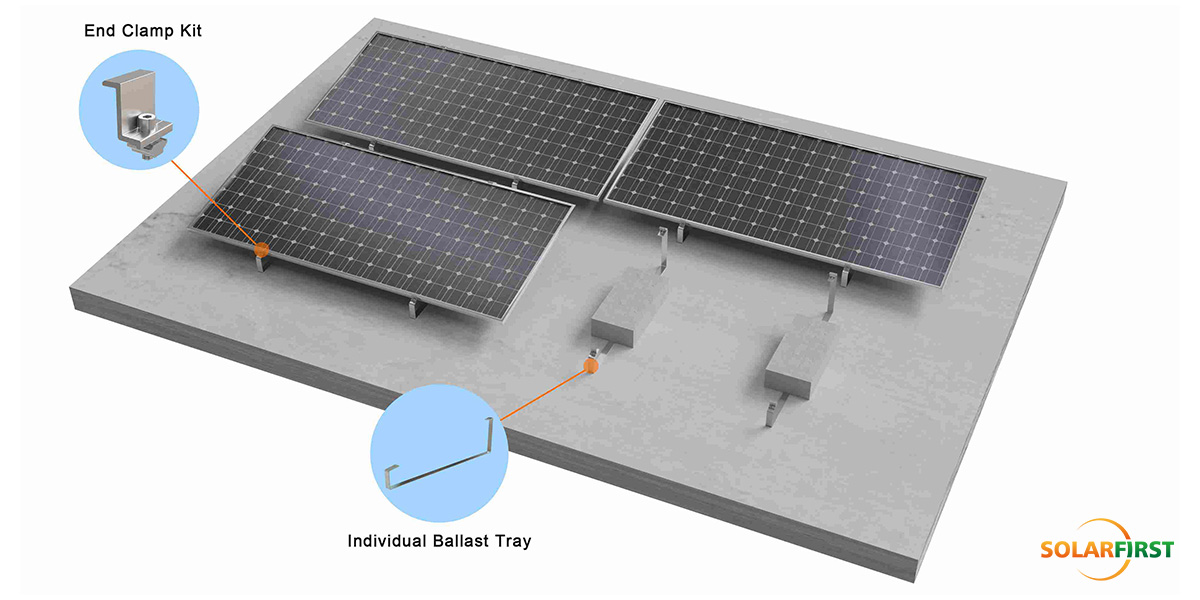

02 Accessory schematic diagram

03 Product Components

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Ground/Concrete Roof |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | 10°, 15°, 20° |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Residential concrete flat roof

✔ Cement flat roof of commercial buildings

✔ Ground-mounted photovoltaic power station projects

06 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :